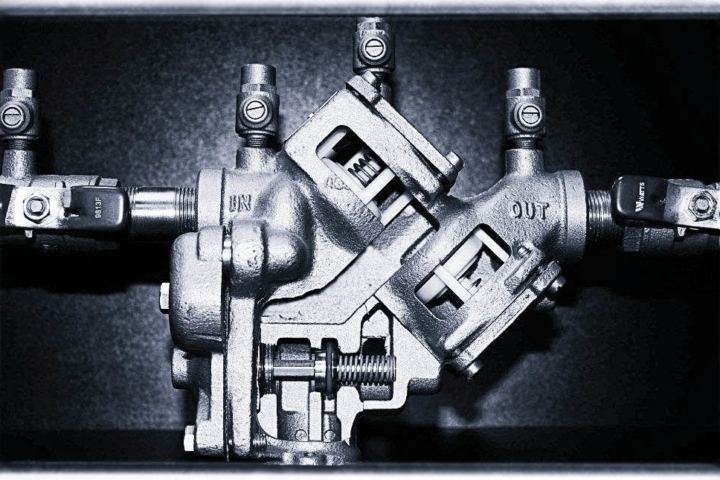

Backflow Services

Testing & Certification

Experienced backflow prevention testers you can trust.

Michigan Plumbing Code requires all installed backflow preventers to be tested regularly, in most cases annually. Backflow Prevention Services has the experience to test all residential and commercial assemblies properly. We work closely with our customers and authorities to satisfy your annual backflow testing compliance requirements.

Repair

Professional backflow preventer repairs from expert technicians.

If your backflow preventer doesn’t pass during annual testing, you may be able to avoid a costly replacement! Our ASSE 5130 Certified Licensed Plumbers provide backflow preventer repairs for residential and commercial customers. No matter the make, model, or problem, our technicians are certified, licensed, and experienced to get the job done.

Installation

Hassle-free backflow preventer install services.

If you need help with a backflow preventer install, we’ll have a properly equipped technician onsite to survey and assess as needed, and you’ll receive a clear quote you can understand. Upon approval, we’ll coordinate with city officials for any permits and water shutoffs to complete your installation, saving you time and headaches!

System Design

Commercial and residential backflow preventer design done right.

When it comes to system design, our expertise and experience will ensure your project is stress-free. Our expert technicians work with property owners and managers to assess current systems and coordinate with city officials and inspectors. From a clear quote to a timeline you can rely on, you’re in good hands with Backflow Prevention Services.

Quick support

To schedule a free estimate, required annual testing, or to learn more about our services, call

1-877-290-4003 or fill out the form below — we will be in touch soon!